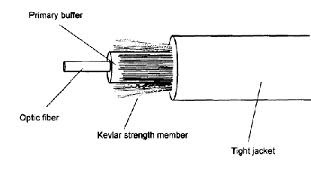

Simplex Fiber Cables

A single cable structure with a single fiber. Simplex cable varieties include 1.6mm & 3mm jacket sizes.

Duplex Fiber Optic Cable

Duplex-zip. This cable contains two optical fibers in a single cable structure. Light is not coupled between the two fibers; typically one fiber is used to transmit signals in one direction and the other receives.

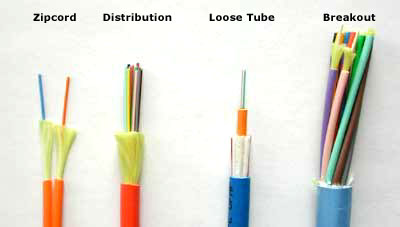

Distribution Fiber Cables

This compact building cable consists of individual 900µm buffered fiber, is smaller in size and costs less than breakout cable. Connectors may be installed directly on 900µm buffered fiber at breakout box location.

Breakout Fiber Cables

Breakout cables are also called fanout cables. In tight buffered cables each fiber is only a 900um tight buffered fiber, but in breakout cables every fiber is a subcable by itself. Each fiber has a 2~3mm jacket, then outer jacket covers these subcables, aramid yarn and ripcord inside. This design allows users to divide the cable to serve users with individual fibers, without the need for patch panel. Breakout cable enables the quick installation of connectors onto 2+mm robust jacketed fiber.

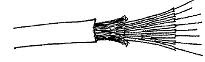

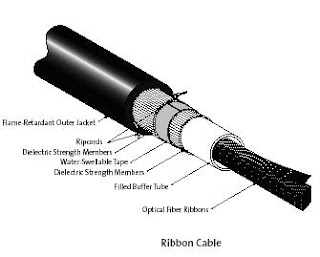

Ribbon Fiber Cables

Consists of up to 12 fibers contained side by side within a single jacket. Often used for network applications and data centers.

LSZH Fiber Cables

Low Smoke Zero Halogen cables are offered as an alternative for halogen-free applications. Less toxic and slower to ignite, they are a good choice for many internal installations. They are available as simplex, duplex and 1.6mm designs. This cable may be run through risers directly to a convenient network or splicing closet for interconnection.

2. Outdoor Fiber Cable

Indoor/outdoor Tight Buffered Fiber Cables

Indoor/outdoor rated tight buffered cables have riser and plenum rated versions. These cables are flexible, easy to handle and simple to install. Since they do not use gel, the connectors can be terminated directly onto the 900um fiber without difficult-to-use kits. This provides an easy and overall less expensive installation.

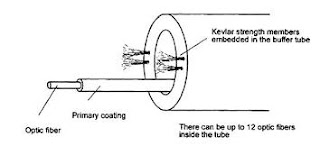

Outdoor Loose Tube Fiber Optic Cables

Tube encloses multiple coated fibers that are surrounded by a gel compound that protects the cable from moisture in outside environments. Cable is restricted from indoor use, typically allowing entry not to exceed 50 feet.

Indoor/Outdoor Dry Loose Tube Fiber Optic Cable

This cable is suitable for both indoor and outdoor applications. One advantage of this cable is that it eliminates the need for a splice or connector at the point where the cable transitions between an outdoor and indoor environment.

3. Aerial/Self-Supporting

Figure 8 Fiber Optic Cables (Aerial/Self-Supporting Fiber Cables)

Figure 8 (aerial/self-supporting) fiber cables are designed to be strung from poles outdoors and most can also be installed in underground ducts. They have internal stress members of steel of steel or aramid yarn that protect fibers from stress.

Aerial cable provides ease of installation and reduces time and cost. Figure 8 cable can easily be separated between the fiber and the messenger. Temperature range -55 to +85°C.

4. Direct-buried

Armored Fiber Optic Cable

Armored cables are similar to outdoor cables but include an outer armor layer for mechanical protection and to prevent damage. They can be installed in ducts or aerially, or directly buried underground. Armor is surrounded by a polyethylene jacket.

Armored cable can be used for rodent protection in direct burial if required. This cable is non-gel filled and can also be used in aerial applications. The armor can be removed leaving the inner cable suitable for any indoor/outdoor use. Temperature rating -40 to +85°C.

5. Submarine Fiber Optic Cable (Undersea Fiber Optic Cable)

Submarine cables are used in fresh or salt water. To protect them from damage by fishing trawlers and boat anchors they have elaborately designed structures and armors. Long distance submarine cables are especially complex designed.

Notice: Loose-Tube Fiber Cable generally cheaper than Tight-Buffered Fiber Cable

Notice: Loose-Tube Fiber Cable generally cheaper than Tight-Buffered Fiber Cable

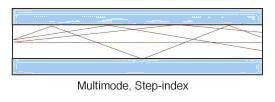

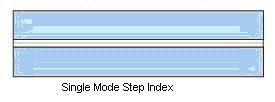

Here are some common Optical Fiber Types

Here are some common Optical Fiber Types